At IBS, we provide a comprehensive range of products and services tailored to support and maintain industrial blower systems. While industrial blowers are designed for durability, they still need regular blower maintenance to operate optimally. Our blower service ensures that your equipment is working efficiency—whether it’s troubleshooting airflow issues, replacing worn components, or fine-tuning the system to prevent future breakdowns.

Airflow is a critical component in many industrial processes. From dust collection and aeration to vacuum systems, industrial blowers are essential for keeping operations running efficiently. Like any high-performance equipment, these systems require proper maintenance and care to function at their best.

In industries like food processing, pharmaceuticals, and electronics, where air purity is essential, an oil free blower is the ideal solution. These units deliver clean, contaminant-free airflow without the use of oil lubrication, making them perfect for environments where hygiene and product integrity are top priorities.

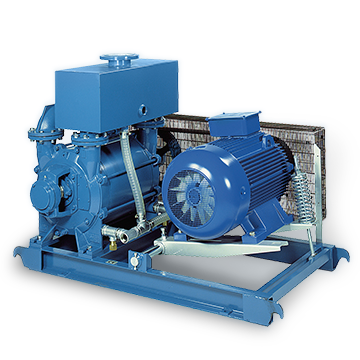

Vacuum pumps are vital in a wide range of industrial applications—from packaging and material handling to medical and laboratory environments. They create the necessary vacuum pressure to move materials, extract gases, or regulate pressure. Keeping these pumps serviced regularly ensures reliable performance and minimises operational disruptions.

Industrial air blower are engineered to move large volumes of air efficiently and are commonly found in HVAC systems, wastewater treatment plants, and pneumatic conveying systems. Selecting the right blower depends on factors such as airflow requirements, pressure needs, and energy efficiency.

For operations looking to reduce energy usage without compromising performance, a turbo blower offers an advanced solution. These units use high speed, modern engineering to provide powerful airflow with minimal energy consumption. They’re particularly popular in sectors like wastewater treatment, chemical production, and power generation.

Industrial blowers and vacuum pumps may not always be in the spotlight, but they are the backbone of many industrial processes. Proper maintenance and selecting the right equipment for your needs can lead to better efficiency, lower operational costs, and improved system performance. Whether you’re due for routine servicing, need repairs, or are exploring new equipment options, IBS is here to keep your systems running at their best.

IBS repairs, services and reconditions everything including compressors, road tanker equipment, filers, valves and seals, and pumps. Portable vacuum units are a regular for repairs and reconditioning, for example the FVP25 portable vacuum unit, as well as other manufacturing machines. A full servicing workover involves the changing of filters and seals, replacing vacuum pump oil, checking vacuum relief valves for wear and tear and substitution where necessary, checking the electrical circuits and their components to identify possible weaknesses and performing risk assessments. Potential problems caused by constant use and checking and re-tensioning or replacing of drive belts are identified and solutions costed and implemented.

IBS repairs, services and reconditions everything including compressors, road tanker equipment, filers, valves and seals, and pumps. Portable vacuum units are a regular for repairs and reconditioning, for example the FVP25 portable vacuum unit, as well as other manufacturing machines. A full servicing workover involves the changing of filters and seals, replacing vacuum pump oil, checking vacuum relief valves for wear and tear and substitution where necessary, checking the electrical circuits and their components to identify possible weaknesses and performing risk assessments. Potential problems caused by constant use and checking and re-tensioning or replacing of drive belts are identified and solutions costed and implemented. While this technology may be one of the oldest still in use, the application of this technology across so many various industries is testament to its tried and tested value to many working environments. Pumps can commonly be found in use in food processing, chemical, commercial, medical, petro-chemical and water supply industries and are valuable for being long-lasting and resistant to wear and tear.

While this technology may be one of the oldest still in use, the application of this technology across so many various industries is testament to its tried and tested value to many working environments. Pumps can commonly be found in use in food processing, chemical, commercial, medical, petro-chemical and water supply industries and are valuable for being long-lasting and resistant to wear and tear.